ADDRESSABLE FIRE ALARM SYSTEM

The ACSP system is designed to effectively detect a fire as early as possible, visually or acoustically alert occupants as well as notify appropriate services.

Pinpointing the location of and quickly reacting to potential fires, enables the immediate start of fire-fighting and successful evacuation of occupants from the endangered area.

The ACSP system is designed to protect various locations, such as:

hotels

office buildings

production plants

shopping centres

public buildings

transport hubs

The heart of the system

The main unit of the ACSP Addressable Fire Alarm System, or the device that controls all the system components, is the ACSP-402 fire alarm control panel.

System architecture

The ACSP-402 supports up to two loops with 128 addressable devices per loop. It can supports radial wiring with support for up to 4 radial lines. The control panel also accepts loops with optional branches or side lines, of addressable devices.

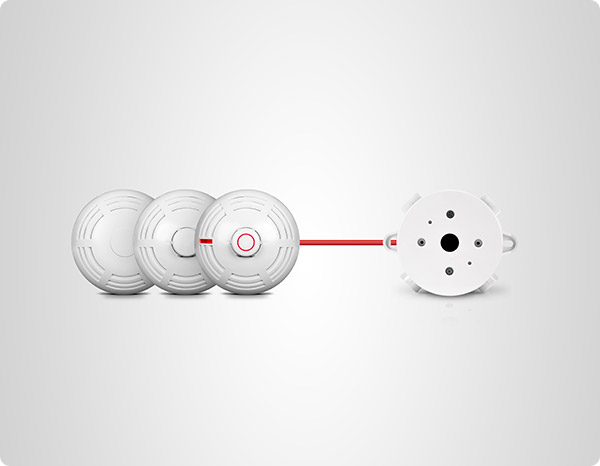

Conventional devices

The system can be expanded with conventional detectors and manual call points. These are wired into side line modules connected to addressable loops or radials.

Clear division of the system

The effective and precise identification of where a fire has been detected is a result of dividing the system into as many as 256 unique zones. A single detection zone can feature up to 32 devices. Addressable sounders and indicators can also signal events in individual parts of the system.

SATEL ACSP

The most tragic consequences of fire can be avoided

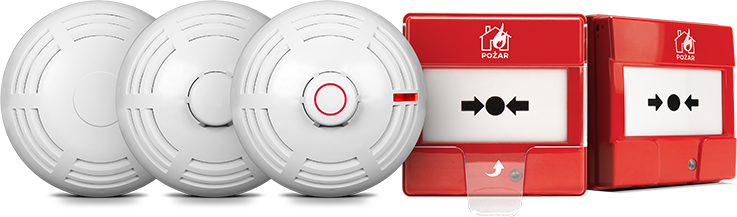

Effective detection

The ACSP system can be fitted with a range of addressable devices for fire alarm activation including detectors and manual call points. Detectors are designed to respond to a fire autonomously whilst call points allow occupants to report a fire anywhere in the building.

detectors

smoke, heat and multi-sensor detectors

manual call points

for indoor and outdoor use

Side line module

Using the MLB-400 conventional side line modules, the control panel can also support conventional detectors and manual call points.

Loud acoustic signalling

In response to alarm signalling received from detectors and call points, the control panel can trigger addressable sounders. The option of activating devices with specific addresses allows for location-specific alarms in different parts of the facility.

The number of addressable signalling devices in the system can be increased by connecting conventional sounders to special outputs on the ACSP-402 control panel.

Automatic notification of emergency services

The ACSP-402 control panel is fitted with fault warning and fire alarm signal transmission outputs. Therefore if the panel is connected to an alarm receiving centre, it is possible to automatically and immediately call out the emergency services. This functionality minimises the time between the detection of a fire and the emergency response.

Support for third-party devices

Both the ACSP-402 and the MIO-400 modules are equipped with programmable inputs and outputs. This makes it possible for the control panel to both monitor and control third-party life safety equipment and systems such as a smoke and heat exhaust ventilation systems, fire doors or fire suppression systems.

The ability to monitor the status and control other third-party equipment such as lift controllers, is another of the ACSP-402’s advantages. It is also possible to connect the control panel to an access control system or voice alarm system.

Effective fire detection

For each detection zone, it is possible to select one of 19 alarm variants in one- and two-stage modes. They correspond to different, specific algorithms used to detect a fire at the earliest stage. The selection of the best alarm type is intended to match the system operation to the conditions in the zone.

Smoke detectors can make use of interactive sensitivity in any given zone. What does it mean? When one detector detects small amounts of smoke, the others switch to an higher sensitivity mode for faster and also more reliable confirmation of a potential fire.

How the DRP-400 detector works

No false alarms

The correct selection of the alarm type in individual zones has a direct impact on reducing the number of false alarms. One way to reduce the occurrence of such alarms is the proper configuration of the detectors. For this purpose, there is an option available to change the sensitivity depending on the staff’s schedule – lower sensitivity when people are present in the facility, and higher sensitivity when the facility is empty.

As an additional protection against false alarms, smoke detectors have an adaptive detection threshold. This ensures that, regardless of the changing contamination level of the optical chamber, the detectors always maintain sensitivity at the same level.

DRP-400 detector –

contamination compensation

Optical signalling

The ACSP system includes addressable remote indicators. These devices can be linked to a zone, a group of devices or any other single system element. As a result, the indicator will visually notify occupants about zone or group events – not only alarms, but also faults or disablements.

If there is no link to a specific element, the indicator notifies about events occurring system-wide. Addressable status indicators have an advantage over their conventional counterparts in that they do not need to be directly connected to the selected detector to signal an alarm triggered by it, which reduces costs and simplifies installation.

WZ-400 – fire alarm

WZ-400 – fault notification

Convenient remote control

Up to 1,000 metres!

The ACSP system can be operated using the APSP-402 repeater panel, which can be located up to 1 km away from the control panel. The system is controlled from the repeater panel in the same way as from the control panel – the user gains full access to information about the system as well as to all its functions. An additional advantage of such a solution is that personnel do not need to be trained to use equipment other than the control panel.

System status overview from any location

Remote access to the system status is available using the Virtual APSP app. It is available in both desktop and mobile.

Encrypted communication with the control panel is via the ethernet module. It is possible to not only check maintenance-related issues but also to view current alarms and the full event log.

Convenient and easy to set up

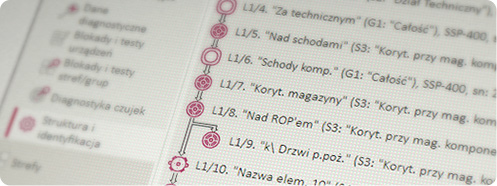

The ACSP system can configured using the integrated LCD and keypad. The other more convenient and user-friendly method is the ACSP Soft application.

As part of the identification process, the control panel automatically detects the topology and all loop devices, and the structure is immediately mapped graphically in the software.

As a result of the automatic identification process, the system is ready for operation in its basic configuration.

The software improves the troubleshooting of possible installation problems related to cabling and makes it easier to pinpoint them. Also a loop component verification feature is available, which searches for changes that have been made since identification was last used.

ACSP Soft application

Easy testing

The option to perform a single-person walk-test of the system as well as sending e-mails including such information as contamination of smoke detectors, are some of the solutions aimed at improving the maintenance of the system.

Cost saving

In addition to enhancing usability, some of the solutions employed within ACSP are intended to reduce the costs of system implementation and operation.

the option of connecting existing parts of a conventional solution into the system using the conventional side line module

the option of carrying out the single-person walk-test of detectors and manual call points, without involving additional personnel

reduced cabling in the system due to the use of addressable remote indicators

built-in backup power supply with a single 12V battery as the emergency power supply – both for the control panel and repeater panel

dzięki użytym w MIO-400 przekaźnikom o dużej obciążalności można bezpośrednio sterować różnymi urządzeniami

Example system diagram

Why use ACSP?

precise location of the at-risk area due to device addressing

solutions to reduce system costs – such as a single backup battery

effective features to speed up maintenance, including the single-person walk-test

advanced diagnostics for faster identification of possible irregularities during system operation or individual devices

easy and convenient programming

clear system status in the mobile and desktop applications

integration with the INTEGRUM software for the visualisation of the current system status

optional remote operation with the repeater panel

special inputs/outputs for monitoring and controlling third-party systems such as a smoke ventilation systems or lift controllers

possibility of integrating existing parts of a conventional CSP solution into the system

Fast and convenient system design with the SSPX configurator

The SSPX hardware configurator is a user-friendly and convenient tool for designing fire alarm systems using SATEL products . The program has a highly intuitive interface, which makes creating projects fast and efficient.

Smart VLOG

Smart VLOG