SERVICES

SATEL Toolroom offers a wide range of services

- designs of plastic products

- injection moulding simulation

- design of injection moulds

- manufacturing of injection moulds according to own and customer's documentation (max. dimensions 600x800)

- design and manufacturing of two-component moulds (max. dimensions 600x800)

- manufacture of press and die cast moulds according to our own and customer's documentation (max. dimensions 600x800)

- manufacture of punching dies and press tools based on our own and customer's documentation (max. dimensions 600x800)

- precise mechanical and electro-erosive machining of metal elements

- design and manufacturing of technological equipment

- overhauls and repairs of injection moulds and press tools

- measurement of objects on three-axis measuring machine

- laser welding

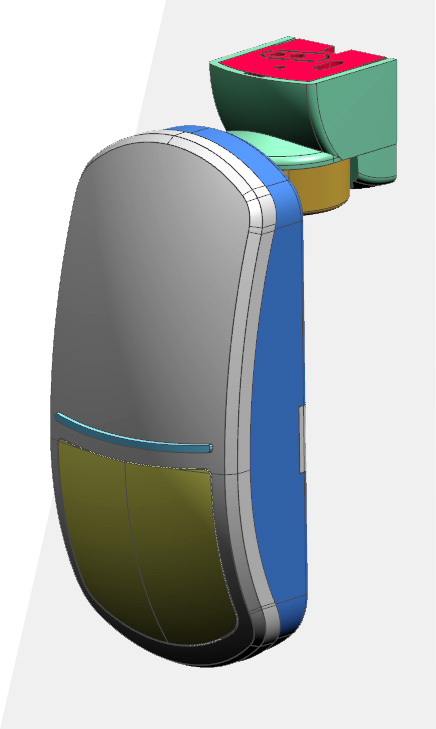

Design of moulded parts

The Toolroom offers complete designs of plastic elements and devices, also in cooperation with SATEL’s own industrial design studio, which uses specialized Siemens CAD/CAM NX software. Our engineering staff has extensive design and technological experience in various fields of industry.

Demonstration or functional models can be made using rapid prototyping methods before work on the injection mould begins. The models or target components can be tested electrically and mechanically using laboratory equipment.

Demonstration or functional models can be made using rapid prototyping methods before work on the injection mould begins. The models or target components can be tested electrically and mechanically using laboratory equipment.

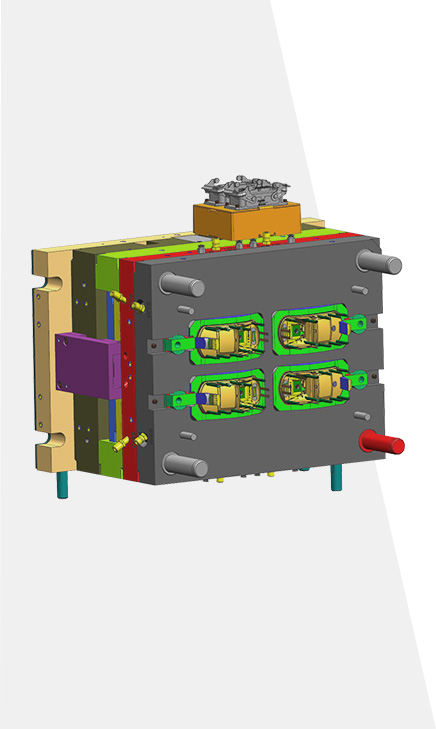

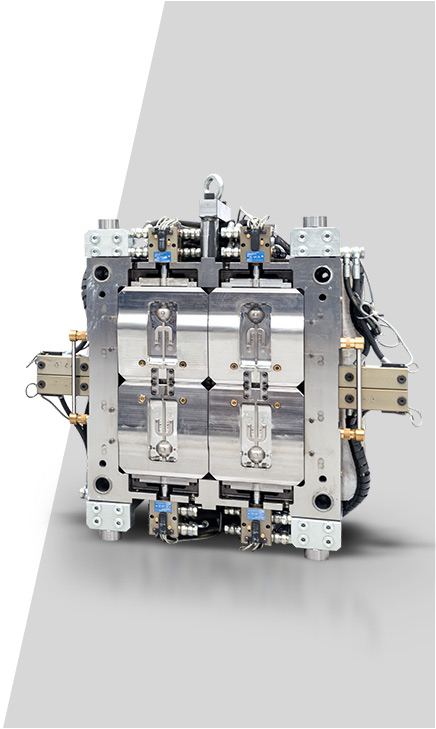

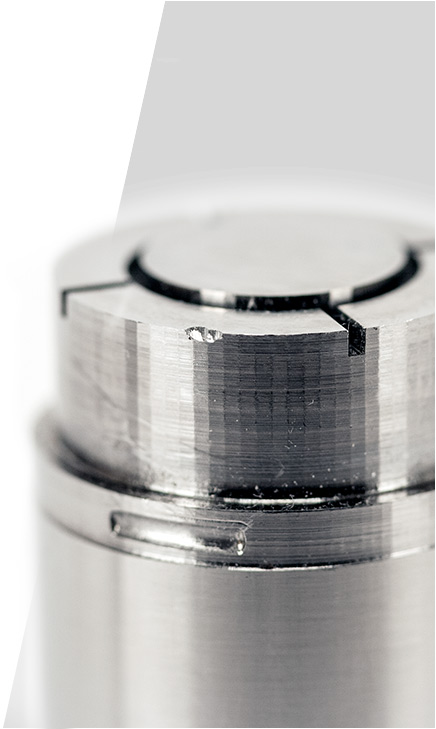

Injection moulds

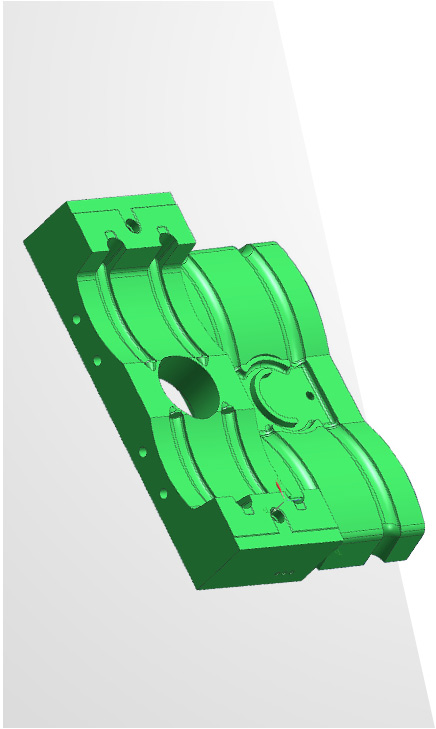

Injection moulds for plastics designed and manufactured at the Toolroom are created with the help of advanced Siemens CAD/CAM NX software.

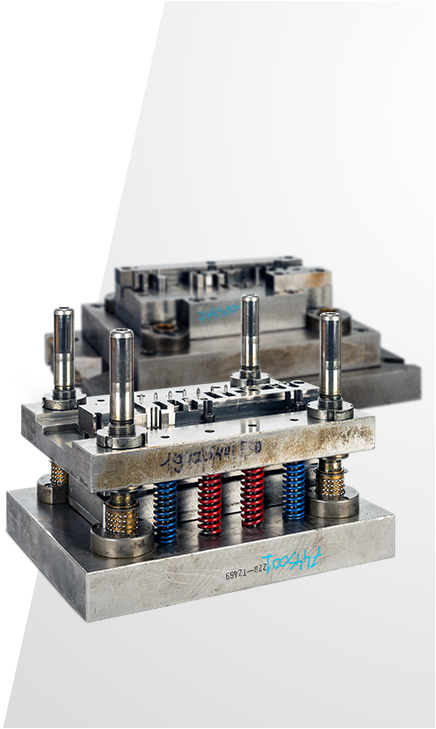

Mould components are made on precise and numerically controlled machine tools. Solutions of renowned suppliers such as HASCO, FCPK etc. are used. We make hot- and cold-runner moulds, which can be equipped with hydraulic or pneumatic drive mechanisms.

Injection moulds manufactured in our Toolroorm are covered by a full guarantee. We also provide post-warranty service, repair and upgrading services.

We can make injection moulds according to the documentation provided by the customer. It is also possible to test a mould and make a test batch of moulded parts.

Mould components are made on precise and numerically controlled machine tools. Solutions of renowned suppliers such as HASCO, FCPK etc. are used. We make hot- and cold-runner moulds, which can be equipped with hydraulic or pneumatic drive mechanisms.

Injection moulds manufactured in our Toolroorm are covered by a full guarantee. We also provide post-warranty service, repair and upgrading services.

We can make injection moulds according to the documentation provided by the customer. It is also possible to test a mould and make a test batch of moulded parts.

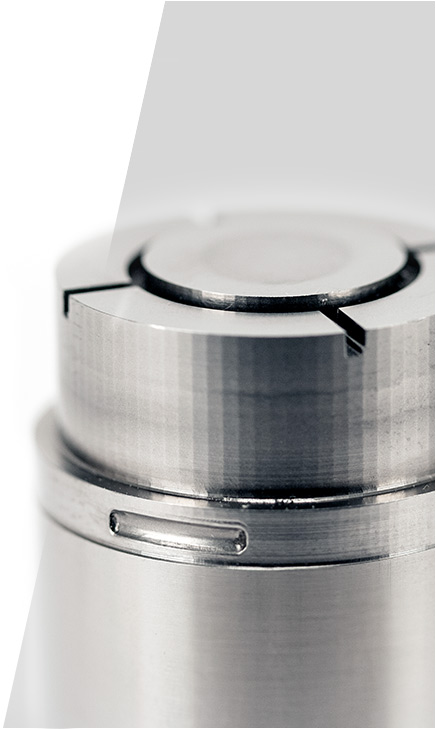

Moulds for two-component injection

The Toolroom can also design and manufacture moulds for two-component injection. This advanced plastic processing technology can be used to manufacture elements from two different types of plastics in a single process.

Two-component moulds are both complex and precise. Components made of hard plastic and thermoelastomer used as gaskets are among the most frequently made parts of this type.

We produce injection moulds for the following injection methods:

Two-component moulds are both complex and precise. Components made of hard plastic and thermoelastomer used as gaskets are among the most frequently made parts of this type.

We produce injection moulds for the following injection methods:

- transfer of the workpiece from socket A to socket B

- rotary table

- overmoulding of plastic or metal inserts

Die cast moulds

The Toolroom can produce die cast moulds for aluminium products. Moulds can be made according to our own and customer’s documentation.

Press and blanking tools

SATEL Toolrom can also design and produce its own stamping and blanking tools, in accordance to our own or supplied by customer design documentation. We can make single- and multi-stage press and blanking tools.

Blanking tools can be made with sintered carbide elements.

Precise CNC machining

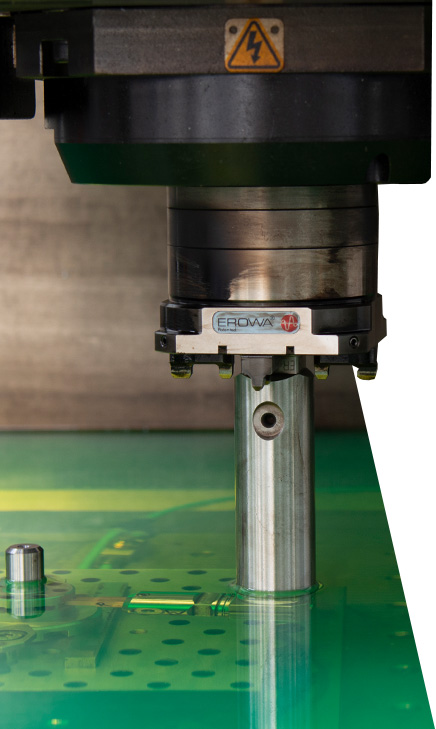

The Toolroom offers precise machining of metal and plastic parts. This process is carried out on modern and highly accurate CNC machine tools.

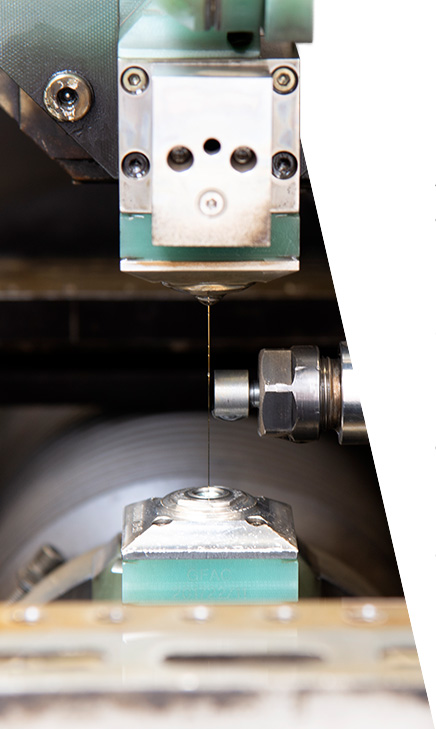

Machining technologies include turning, milling, grinding, hollowing and wire cutting. Machining of tempered steel up to 60 HRc and smooth five axis milling are possible.

Machining technologies include turning, milling, grinding, hollowing and wire cutting. Machining of tempered steel up to 60 HRc and smooth five axis milling are possible.

Modernisations and repairs

Services provided by the Toolroom also include repairs and modernisation of injection moulds and other technological tools and equipment. The repair process consists of assessment of tool wear, which is carried out together with customers to determine the scope of necessary regeneration. Elements selected for repair can be either replaced with new ones or regenerated, e.g. by welding on worn-out edges. The equipment of our Toolroom enables precise welding of even very small and delicate mould elements. We can also sharpen cutting elements while reconditioning blanking dies.

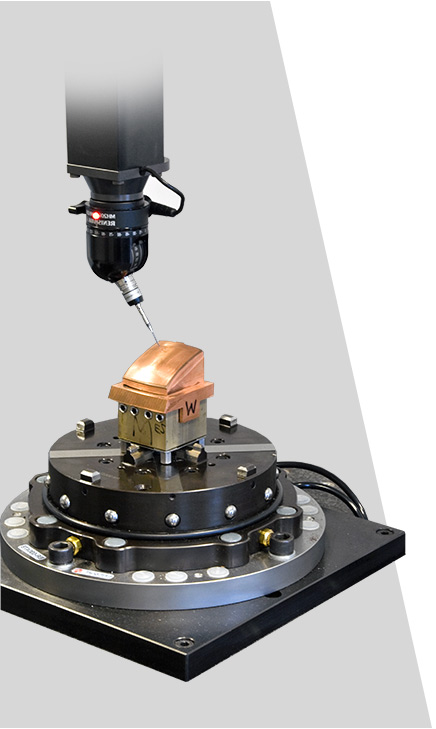

Measurements

Control measurements and verification of the quality of various components are two other services offered by the Toolroom. A coordinate measuring machine is used to carry out this process.

The machine’s software can help generate measurement reports in a variety of formats and graphic forms.

The machine’s software can help generate measurement reports in a variety of formats and graphic forms.

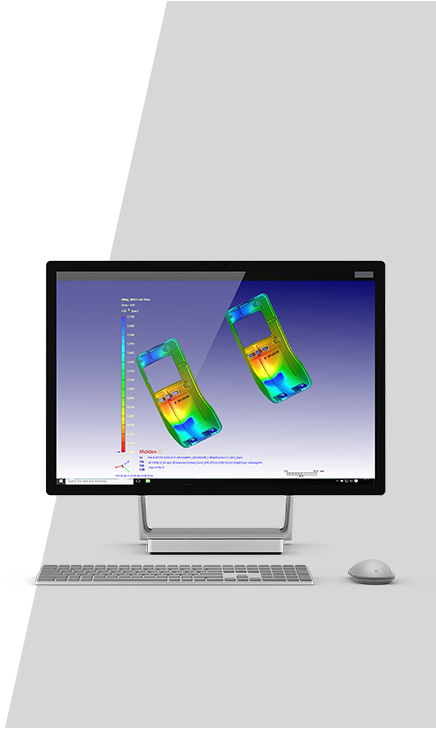

Injection moulding simulation

The Toolroom offers simulation of the injection moulding process to help identify potential problems and find solutions at the initial stage of mould development.

The simulation is carried out using the mouldex3D software. Its advanced calculation algorithms take into account the design of the gating and mould cooling system as well as the processing parameters and characteristics of the injection moulding machine. As a result, potential defects such as warping can be precisely reproduced. It is possible to simulate injection moulding of filled plastics (e.g. glass fibre) and two-component parts.

The simulation is carried out using the mouldex3D software. Its advanced calculation algorithms take into account the design of the gating and mould cooling system as well as the processing parameters and characteristics of the injection moulding machine. As a result, potential defects such as warping can be precisely reproduced. It is possible to simulate injection moulding of filled plastics (e.g. glass fibre) and two-component parts.